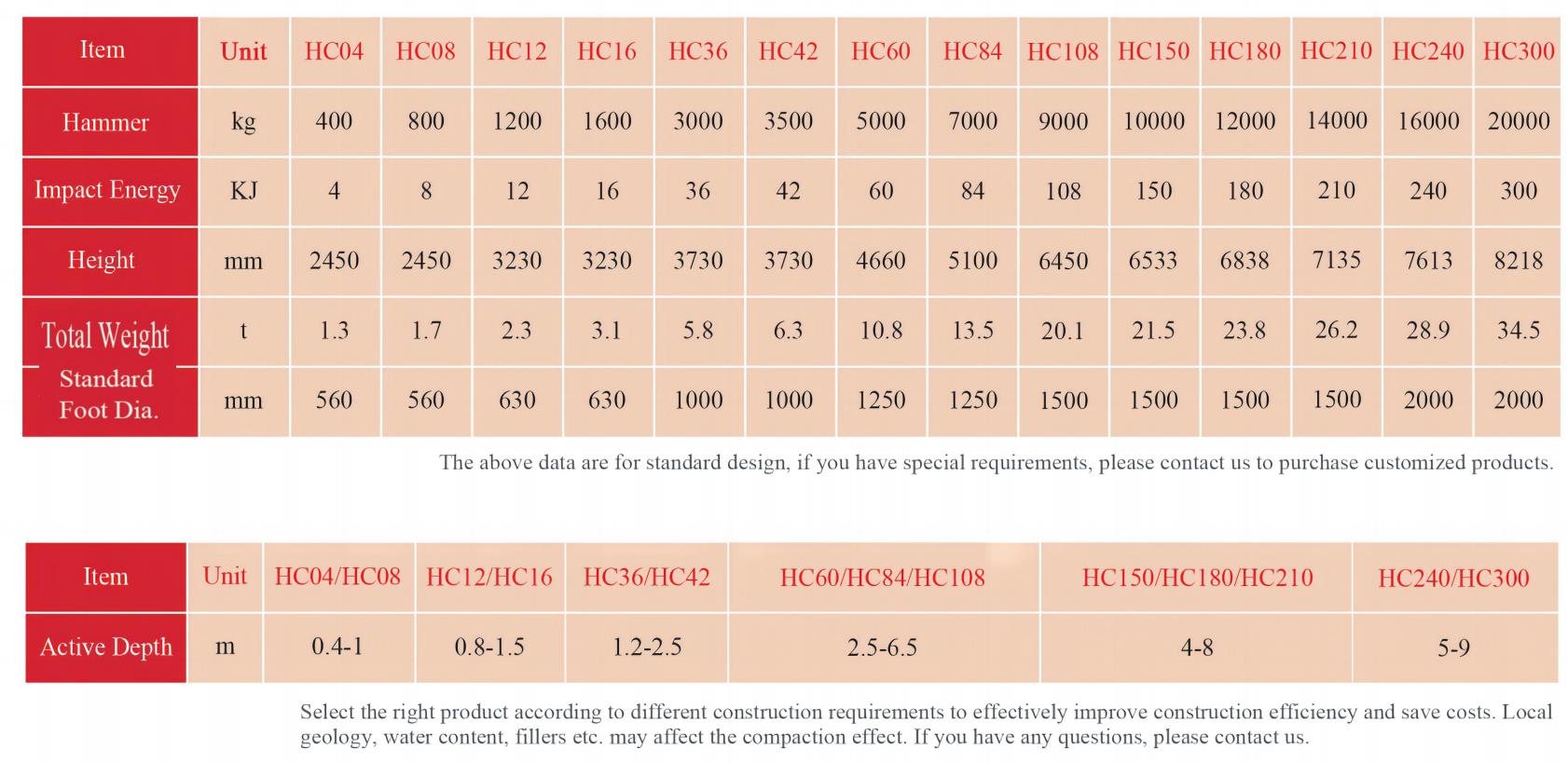

| Project | Unit | HC04 | HC08 | HC12 | HC16 | HC36 | HC42 | HC60 | HC84 | HC108 | HC150 | HC180 | HC210 | HC240 | HC300 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hammer Mass | kg | 400 | 800 | 1200 | 1600 | 3000 | 3500 | 5000 | 7000 | 9000 | 10000 | 12000 | 14000 | 16000 | 20000 | ||

| Impact Energy | KJ | 4 | 8 | 12 | 16 | 36 | 42 | 60 | 84 | 108 | 150 | 180 | 210 | 240 | 300 | ||

| Working Height | mm | 2450 | 2450 | 3230 | 3230 | 3730 | 3730 | 4660 | 5100 | 6450 | 6533 | 6838 | 7135 | 7613 | 8218 | ||

| Standard Tamping Plate Diameter | mm | 560 | 560 | 630 | 630 | 1000 | 1000 | 1250 | 1250 | 1500 | 1500 | 1500 | 1500 | 2000 | 2000 | ||

| Working Mass | t | 1.3 | 1.7 | 2.3 | 3.1 | 5.8 | 6.3 | 10.8 | 13.5 | 20.1 | 21.5 | 23.8 | 26.2 | 28.9 | 34.5 | ||

| Effective Depth | m | 0.4-1.0 | 0.8-1.5 | 1.2-2.5 | 2.5-6.5 | 4-8 | 5-9 | ||||||||||

| The above data are all standard design,if you have special needs,please contact us to purchase customized products. | |||||||||||||||||

| Select the appropriate product according to different construction requirements will mprove the construction efficiency effectively and save costs.Geographical features,water content,fillers etc.may affect the tamping effect,please feel free tocontact us if you have any questions. | |||||||||||||||||

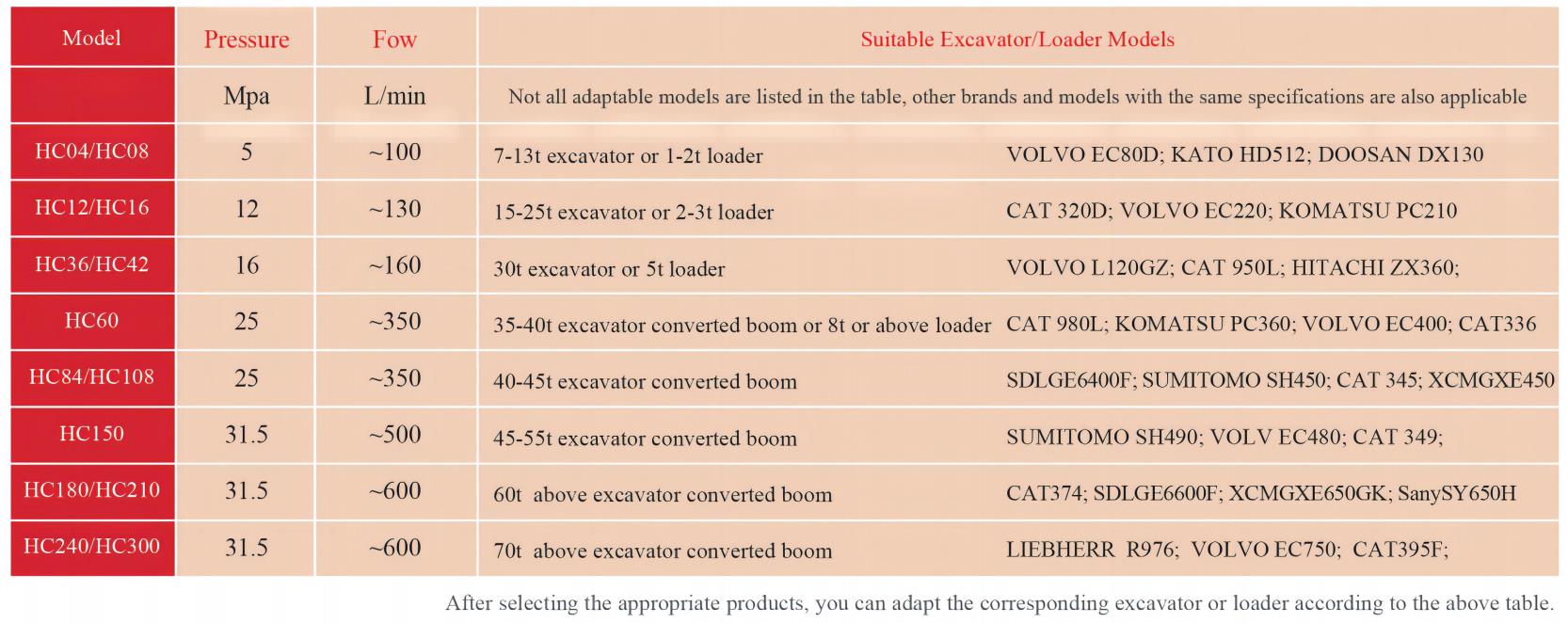

| Model | Working Pressure (Mpa) | Working Flow (L/min) | Suitable Excavator/Loader Models | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HC04/HC08 | 5 | ~100 | 7-13t excavator or 1-2t loader (e.g., VOLVO EC80D, KATO HD512, DOOSAN DX130) | ||||||||||||||

| HC12/HC16 | 12 | ~130 | 15-25t excavator or 2-3t loader (e.g., CAI320D,VOLVOEC220,KOMAISU PC210) | ||||||||||||||

| HC36/HC42 | 16 | ~160 | 30-40t excavator or 5-6t loader (e.g., VOLVO L120GZ, CAT 950L, HITACHI ZX360) | ||||||||||||||

| HC60 | 25 | ~350 | 35-40t excavator converted boom or 8T or above loader (e.g., CAT980L,KOMATSU PC360,VOIVO EC400, CAT336) | ||||||||||||||

| HC84/108 | 25 | ~350 | 40-45t excavator converted boom (e.g., SDLGE 6400F,SUMITOMO SH450,CAT 345,XCMG XE450) | ||||||||||||||

| HC150 | 31.5 | ~500 | 45-55t excavator converted boom (e.g., SUMITOMO SH490,VOLVO EC480,CAT 349) | ||||||||||||||

| HC180/HC210 | 31.5 | ~600 | 60t above excavator converted boom (e.g., CAT374,SDLG E6600F,XCMG XE650GK,Sany SY650H) | ||||||||||||||

| HC240/300 | 31.5 | ~600 | 70t above excavator converted boom (e.g., LIEBHERR R976,VOLVO EC750,CAT 395F) | ||||||||||||||

| After selecting the appropriate products,you can adapt the corresponding excavator or loader according to the above table. | |||||||||||||||||

Soil compaction is used to densify loose granular soils and loam fill and industrial brownfield sites for surface compaction, foundations, liquefaction mitigation, and waste stabilization. Rapid Impact Compaction is a foundation improvement method that effectively compacts loose granular soils using hydraulic hammers that repeatedly strike an impact plate on the ground at 30 to 80 times per minute. RIC is effective for compaction of upper layers of ground typically up to 1- 9m dept. RIC technology is suitable for a wide range of non-cohesive soils, and is particularly suited to the compaction of gravel and sand.

The most common models mounted on excavators are HC150 HC180.

How it is applied?

The compaction foot installed to the hammer is placed on the marked location. After positioning the hammer, operated from the excavator cabin, is activated. Inside the frame, a drop weight is lifted to the predetermined height and dropped onto the compaction foot. The foot remains in contact with the ground while the drop weight repeats its sequence up to 80 blows/min. This process is repeated until the compaction criteria are met. The operator positions the hammer to the next marked location and repeats the process.

Soil compaction is used to densify loose granular soils and loam fill and industrial brownfield sites for surface compaction, foundations, liquefaction mitigation, and waste stabilization.

The excavator converted rapid impact compactor utilizes the hydraulic power output from the excavator to continuously strike and tamp the ground. With high efficiency, high flexibility and easy operation, the excavator conversion rapid impact compactor is widely used in various construction scenarios and can meet the tamping needs of different foundations.Proper soil compaction is crucial for both small and large construction projects because it increases soil density and load bearing, ensuring the stability, durability, and longevity of buildings and structures. Choosing the right compaction equipment is the starting point for any effective compaction strategy.

The most common models mounted on loaders are HC42 .

Get Quote

Description

Rapid Impact Compaction is a high-frequency, controlled energy compaction technique used to densify surface layers, mitigate liquefaction risks or improve the bearing capacity of specific soil types up to 9 meters with minimum impact on the job site environment.

Selected Use Cases(More Projects)

Rapid Impact Compactor HC180 Click here to view details

Application of Rapid impact compactor in Guangzhou West Second Ring Highway (HC ... Click here to view details

The combination of 36KJ Rapid impact compactor and Lonking 50 loader has signifi... Click here to view details