Birthplace of China's rapid impact compaction machine,Inventor: Cao Bin as chief engineer

ricmadeinchina@gmail.com

ricmadeinchina@gmail.com

Birthplace of China's rapid impact compaction machine,Inventor: Cao Bin as chief engineer

ricmadeinchina@gmail.com

Hydraulic Rapid Impact Compactor is a new type of foundation construction machinery that uses its special hydraulic hammer technology to impact soft soil foundation. It can be quickly fixed on loaders, excavators and crawler lifts. It has good flexibility, controllability and high efficiency. It is a special high-speed impact machine. It adopts numerical control, full hydraulic drive and adjustable impact energy. It can be used for plane, inclination, step and channel impact, and the depth can reach 3-10m.

Features

1) Program control:

Hydraulic Rapid Impact Compactor can be single impact and PLC impact, and the energy preset and step preset of single impact and impact energy;

It can automatically record PLC impact energy, times and single impact energy, total operation time and times. Easy for energy control and data acquisition;

It can automatically monitor the collision system.

2) Simple and reliable:

Hydraulic Rapid Impact Compactor can use the hydraulic power of loaders and excavators without other power, and the connection is simple, fast and reliable.

Its drive and control system has high integration, simple structure and easy maintenance.

3) Simple and safe:

Hydraulic Rapid Impact Compactor can be directly installed on loaders, excavators and crawler lifts, with good flexibility, controllability, high efficiency and convenient use.

Its feet are always in contact with the foundation, which can avoid potential hazards and flying chips in the process of falling.

Main functions:

Various impact plates, crushing devices and pile guide devices can be easily replaced, and then combined with loaders, excavators and crawler hoists for impact, crushing and pile driving.

Construction method

Operation method:

because the construction position is at the back of the bridge and culvert, in order to facilitate the walking of machinery, the straight-line operation method is suitable, that is, each single point operation, forward or backward operation to the next point.

Arrangement of operation points:

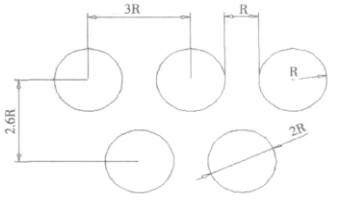

gap type is suitable for gap type construction, the edge of each tamping point is separated by a certain distance, and the points are arranged in an equilateral triangle, that is, the point distribution method with the spacing of 50cm between the edges of each hammer is adopted. According to the experimental parameters, the distance between the center of the rammer at the first row of construction points and the structure is 80cm, that is, the distance from the edge of the rammer to the structure is 30cm, which can ensure the safety of the structure.

The number of working hammers:

according to the previous site experimental data, the tamping effect of the third gear 9 hammer is the best. The working process of the third gear 9 hammer is used in most construction positions, and the construction process of the second gear 9 hammer or 12 hammer is used in the first row near the structure.

Construction effect display

Address: Tai'an, Shandong, China

Taian Hengda Machinery Co., Ltd

National government certification:鲁ICP备18050468号-9